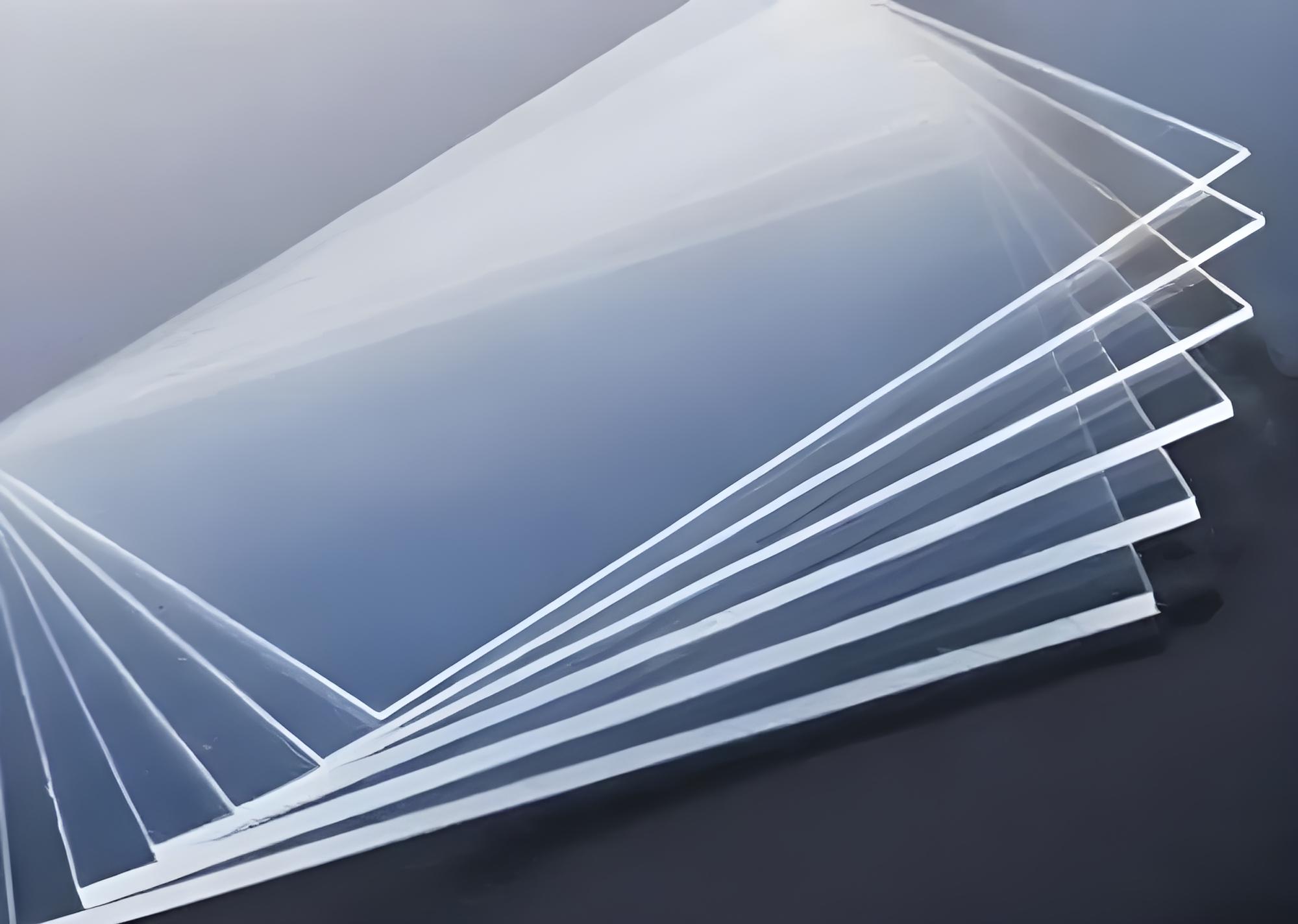

Sunan sinadarai na acrylic shine polymethylmethacrylate (PMMA a Turanci). Saboda gazawar PMMA kamar ƙananan taurin ƙasa, shafa mai sauƙi, ƙarancin tasiri, da ƙarancin gyare-gyaren gyare-gyare, gyare-gyare na PMMA sun bayyana ɗaya bayan ɗaya. Irin su copolymerization na methyl methacrylate tare da styrene da butadiene, haɗakar PMMA da PC, da dai sauransu.

Halin kwarara naPMMAya fi na PS da ABS muni, kuma narke danko ya fi kula da canjin zafin jiki. A yayin aiwatar da gyare-gyaren, an fi canza dankon narkewa bisa ga zafin allura. PMMA shine polymer amorphous tare da zafin jiki mai narkewa fiye da 160°C da zafin jiki na bazuwar 270°C.

1. Zubar da robobi

PMMA yana da wani mataki na sha ruwa, tare da yawan sha ruwa na 0.3-0.4%. Yin gyaran allura yana buƙatar zafi ƙasa da 0.1%, yawanci 0.04%. Kasancewar danshi yana haifar da kumfa, ɗigon iska, da rage nuna gaskiya a cikin narke. Don haka yana buƙatar bushewa. Yanayin bushewa shine 80-90℃kuma lokacin bushewa ya fi 3 hours. Ana iya amfani da kayan da aka sake sarrafa su 100% a wasu lokuta. Ainihin adadin ya dogara da buƙatun ingancin, yawanci fiye da 30%. Dole ne a guje wa abubuwan da aka sake yin fa'ida daga gurɓatawa, in ba haka ba zai shafi bayyana gaskiya da kaddarorin samfurin da aka gama.

2. Zaɓin na'urar gyare-gyaren allura

PMMA ba shi da buƙatu na musamman don injunan gyare-gyaren allura. Saboda girman narkewar sa, yana buƙatar rami mai zurfi da rami mai girma diamita. Idan ƙarfin buƙatun samfurin ya fi girma, ya kamata a yi amfani da dunƙule tare da babban rabo mai girma don ƙarancin zafin jiki. Bugu da ƙari, dole ne a adana PMMA a cikin busassun hopper.

3. Mold da ƙirar kofa

Yanayin zafin jiki na iya zama 60℃-80℃. Diamita na babban tashar ya kamata ya dace da taper na ciki. Mafi kyawun kusurwa shine 5° ku 7°. Idan kana son yin allura 4mm ko sama da samfuran, kwana ya kamata ya zama 7° kuma diamita na babban tashar ya kamata ya zama 8 zuwa 8°. 10mm, gaba ɗaya tsawon ƙofar kada ya wuce 50mm. Don samfuran da ke da kauri na bango ƙasa da 4mm, diamita na tashar ya kamata ya zama 6-8mm

Don samfurori tare da kauri na bango fiye da 4mm, diamita na mai gudu ya kamata ya zama 8-12mm. Zurfin diagonal, fan mai siffa da ƙofofin yanki na tsaye yakamata ya zama 0.7 zuwa 0.9t (t shine kaurin bangon samfurin). Diamita na ƙofar allura ya kamata ya zama 0.8 zuwa 2mm; Ya kamata a zaɓi ƙananan girman don ƙananan danko.

Ramin huɗa na gama gari suna cikin zurfin 0.05, faɗin 6mm, kuma daftarin kusurwa yana tsakanin 30"-1° kuma sashin rami yana tsakanin 35"-1°30°.

4. Narke zafin jiki

Ana iya auna shi ta hanyar allurar cikin iska: daga 210℃zuwa 270℃, dangane da bayanin da mai bayarwa ya bayar.

Fita daga kujerar baya, sanya bututun injin allura ya bar babban tashar bushing, sannan a yi gyare-gyaren allurar filastik da hannu, wanda shine gyaran allurar iska.

5. zafin allura

Ana iya amfani da allura mai sauri, amma don guje wa matsanancin damuwa na ciki, yana da kyau a yi amfani da allurar matakai da yawa, kamar jinkirin-sauri, da sauransu.

6. Lokacin zama

Idan zazzabi ya kasance 260°C, lokacin zama ba zai iya wuce minti 10 ba. Idan zafin jiki ya kai 270°C, lokacin zama ba zai iya wuce mintuna 8 ba.

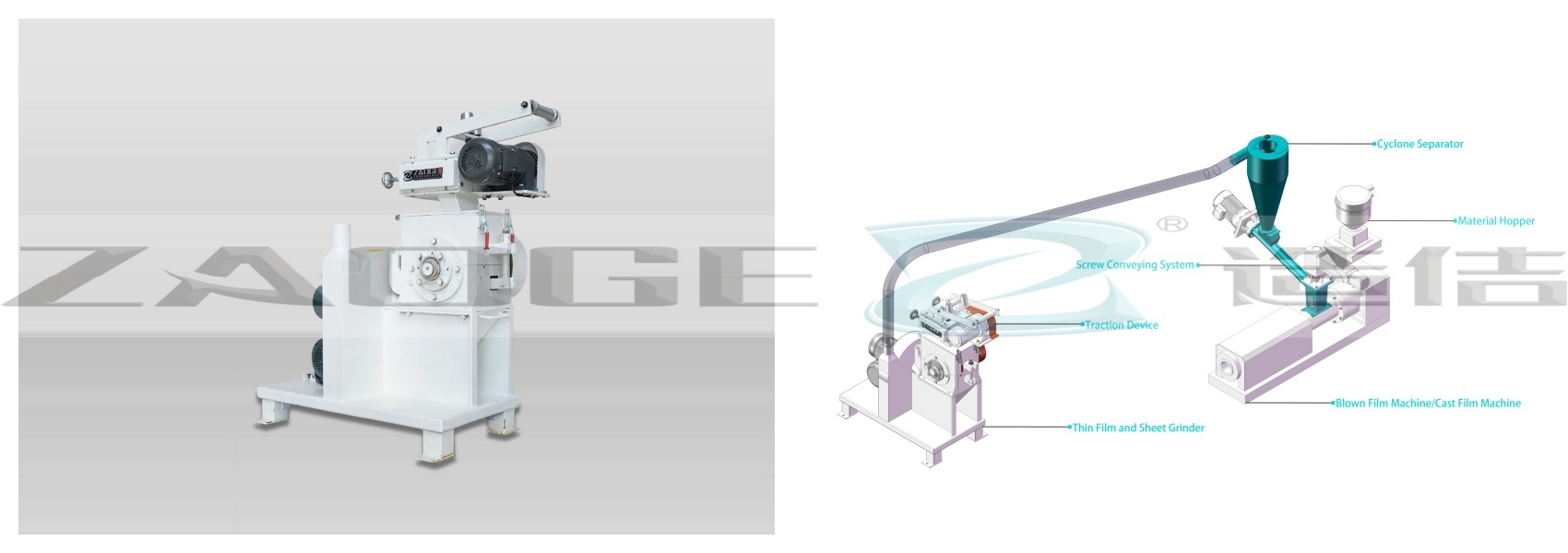

ZAOGE Film Crusherya dace da murkushe nau'ikan kayan ɓata mai laushi da wuyar ƙima tare da kauri na 0.02 ~ 5MM, kamar PP / PE / PVC / PS / GPPS / PMMA fina-finai, zanen gado, da faranti da aka yi amfani da su a cikin kayan aiki, marufi, da sauran masana'antu.

Ana iya amfani da shi don tattarawa, murkushewa da isar da kayan ɓarke gefen da masu fitar da kaya, laminators, injinan zane, da injin faranti suka samar. Misali, kayan da aka murkushe ana jigilar su ta hanyar bututun mai zuwa ga mai raba guguwa, sannan kuma a tura su cikin tashar ciyar da abinci ta hanyar ciyarwa don haɗawa ta atomatik tare da sabbin kayan, don haka ana samun kariyar muhalli nan take da amfani.

Lokacin aikawa: Jul-01-2024